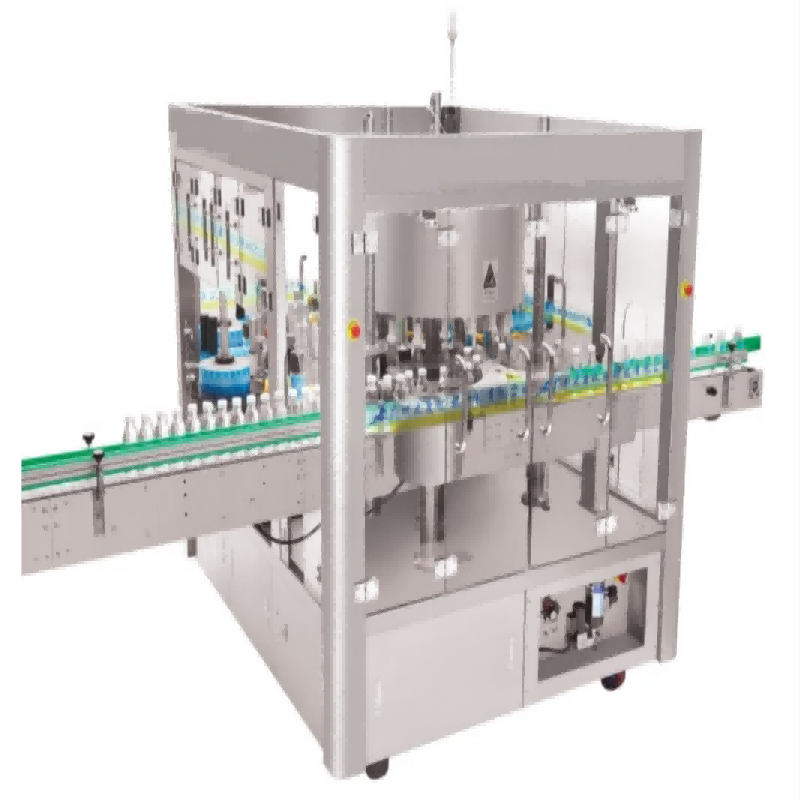

Mashiinka Calaamadaynta Xabagta Kulul ee Wareega Toota ah

Sifooyinka Alaabta

| Nooca: Calaamadeeyaha |

| Sumadda:Gool-galiyay |

| Alaabta sumadda:BOPP,OPP,PVC |

| Sumadda: Qorrax soo baxa Qalabka Sirdoonka |

| La habeeyey: Haa |

| Xidhmada Gaadiidka: Alwaax |

| Codsiga: dhalooyinka PET ee cabitaannada casiirka khudradda, cabitaannada kaarboonaysan, biyo saafi ah iyo biyaha macdanta, iwm |

Summada Alaabta

Mashiinka calaamadaynta, nidaamka calaamadaynta, calaamadeeyaha, mashiinka dhejiska, mashiinka calaamadaynta, mashiinka baakadaha, mashiinka wax lagu duubo, nidaamka baakadaha, nidaamka baakadaha, wax soo saarka biyaha saafiga ah, line-soo-saarka casiirka cabitaanka, line-soo-saarka shaaha, line-soo-saarka CSD.

Faahfaahinta Alaabta

Hordhac

Mashiinka calaamadaynta tooska ah waa qalab ku dhejin kara duubabka warqadaha ama warqadaha warqadaha weelasha ama alaabta la cayimay.Dhabarka calaamaddu waxay la socotaa koollo waxaana si joogto ah loogu habeeyaa warqadda hoose ee siman, iyo habka diirinta summada ee mashiinka calaamadaynta ayaa si toos ah u fujin karta.

Marka weelku gaadho booska lagu ogaanayo isha korantada, kombayutarka nidaamka gudbinta summada kontoroolka.Marka ficil bixinta dalabka la dhammeeyo, gooyaha xawaaraha sare wuxuu gooyaa calaamadda calaamadda. Calaamadda la gooyay waxaa loo diraa nidaamka dhejiska. weel.Maadaama weelku ku jiro xaalad wareeg ah inta lagu jiro wareejinta calaamadda, calaamaddu waxay si habsami leh ugu dhejin kartaa weelka. .

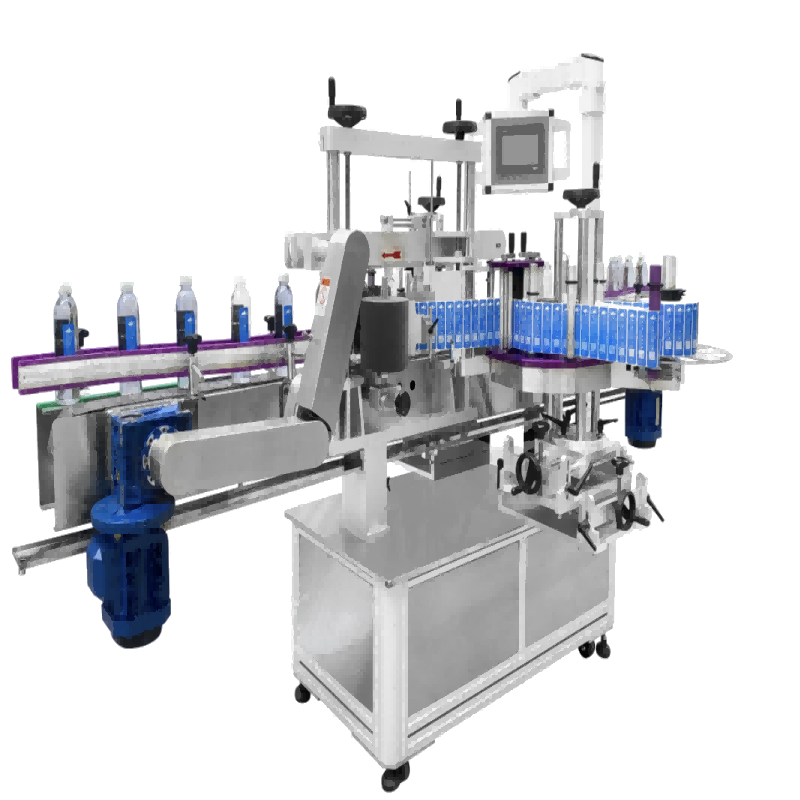

Astaamaha

1. Xawaaraha sare ee madaxa meel badan iyo hagaajinta xagal badan, waxay wanaajisaa baaxadda codsiga mashiinka calaamadaynta, sida calaamadaynta qoorta, hagaajin habboon.

2. Qaadashada tignoolajiyada rullaluleyda laba jibaaran:

Rollerka ugu horreeya wuxuu ciyaaraa doorka kala-soocidda calaamadaha, yaraynta saamaynta calaamadaha dabacsan iyo laalaabtay.

Roller-saxaafadeedka labaad wuxuu door ka ciyaaraa dhimista diiqada warqadda salka iyo yaraynta dhacdooyinka calaamadaha joojinta ee habka wax soo saarka xawaaraha sare leh.

3. Quudiye calaamaduhu wuxuu qaataa taageerada saddex-bar, taas oo ka faa'iido badan taageerada hal-bar ee isla warshadda si loo hubiyo in qalabku uu aad u deggan yahay hawlgalka xawaaraha sare leh oo si wax ku ool ah loo hubiyo saxnaanta calaamadaynta.

4. Nidaamka buuxinta saliidda tooska ah

Waqtiga sifeynta tooska ah ee tooska ah ayaa lagu hagaajiyaa shaashadda taabashada, taas oo saameyn wanaagsan ku leh qaybaha waxayna kordhisaa nolosha adeegga mashiinka.

5.Marka giraangiraha xiddiggu ku xayiran yahay, nidaamku si toos ah ayuu u qaylo dhaamin doonaa oo u joogsan doonaa, oo gacanta ku wareejin doona giraangiraha xiddiggu si toos ah ayuu dib u dejin doonaa.

6.Infinitely variable system xawaaraha

Hagaajin wax soo saarka, kaliya hawlgalka shaashadda taabashada, suunka gudbinta, isbeddelada xawaaraha taayirrada xiddiguhu way isbeddeli doonaan si waafaqsan.Looma baahna inaad waqti iyo dadaal ku bixiso sidii aad u hagaajin lahayd dhammaan qaybaha.

7. Qalabka kor u qaadista otomaatiga ah ee habka dhalada cadaadiska

Beddelka dhaladu way ka duwan tahay mashiinada gacanta ee dhaqameed si loo hagaajiyo habka dhalada cadaadiska, oo leh saxnaanta sare iyo badbaadinta shaqada.

8.Mashiinku wuxuu qaataa albaabka badbaadada isku laabma, kaydinta booska iyo hawlgalka ku habboon.Dhammaan albaabada isku laabma waxay ka samaysan yihiin muraayad adag si loo hubiyo hufnaanta iyo fududaynta u fiirsashada dhaqdhaqaaq kasta oo gudaha ah.Albaabka isku laabma ee leh furaha badbaadada, u shaqee si wax ku ool ah u wanaaji hubinta badbaadada.

Qiyaasaha Farsamada

| Awood | 380V 50/60Hz |

| Awood | 9000BPH-24000BPH |

| Habka sumadda | Sida waafaqsan shuruudaha macmiilka |

| Dhererka calaamadda ugu badan | 210 mm |

| Dhererka calaamadda ugu yar | 15mm |

| Dhererka wejiga shaqada | 1050mm (sida waafaqsan shuruudaha macaamiisha) |

| dhumucda sumadda | ≥0.035mm |

| Calaamadee cabbirka xudunta u ah | Dhexroor gudaha ah 152.4mm; dhexroorka dibadda ee 550mm |

| Cabbirka ugu badan ee koollada | dhexroor ≤ 72mm (ka baxsan baaxadda cabbirka, u baahan tahay in si gaar ah looga hadlo) |

| Summaynta saxnaanta | ± 1mm |

| Saxnaanta | ± 0.3mm |